The Longer LK5 Pro is currently the flagship FDM 3D printer from the Shenzhen-based manufacturer and it’s one of those fairly inexpensive devices that promise to offer a similar experience to the 3D printers that cost a lot more. And, to my surprise, the combination between bare-bones-like design and well-thought-out features works really well for Longer. Indeed, after some basic adjustments, I got some really good benchmark prints, competing with printers that have a higher price tag.

Still, you need to keep in mind that while it’s not very difficult to assemble, you will need a bit over an hour to get everything together and there is some fine tuning that needs to be made which I am not entirely sure will make the complete beginners very happy.

This is true for the entire 3D printing industry since it has not yet found a way to ease the way for new users – I know that most people just want to take the printer from the box and start printing without having to adjust anything.

| Longer LK5 Pro | |

| Check Price | Longer3d.com |

I also know that the people interested in 3D printing aren’t going to be turned off by adjusting things a little bit and the Longer LK5 Pro does reward its users with a color touchscreen LCD that works well, there is a heated bed with an additional glass bed and the manufacturer has also added some stabilizing rods to help reduce the vibrations. Furthermore, the device comes with open sources mainboard, so it’s easy to upgrade the LK5 Pro to your liking. That being said, let’s check the Longer LK5 Pro a bit more in-depth and see whether it can be considered the best 3D printer in its price range.

The Design and Build Quality

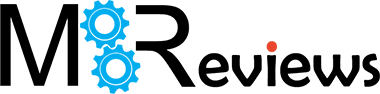

Longer LK5 Pro is not a successor to a regular LK5 since the manufacturer preferred using the terms Pro to signify the use of the same color LCD found on the LK4 Pro and a larger frame. There is obviously some marketing fluff there as well. In any case, the 3D printer, when fully built, is larger than both the LK4 and the LK4 Pro, measuring 22.8 x 21.2 x 26.1 inches (58.0 x 54.0 x 66.3 cm) and weighing 29.8lbs (13.5kg), so yes, you do need to plan ahead where it’s going to be positioned because it does take a lot of space. The good news is that the print size is 11.8 x 11.8 x 9.8 inches (30.0 x 30.0 x 40.0 cm), so you can create very large models.

The 3D printer comes partially pre-assembled, kind of, since the PSU+base is connected to the X-axis arm and extruder, so you do have to assemble everything else. Inside the package, you do get a tall gantry, the screw rod and the supporting beams. These beams are a necessity due to the tall profile of the Longer LK5 Pro to limit the vibrations. And they do work as intended, but there are a few elements that can cause vibrations as you will see in the sections below.

The manufacturer also puts a screw rob bearing bracket to help keep the screw rod into place, an upgrade over the Lk4 which had it exposed and there is also a Z-axis motor, a limiter switch, a filament holder and a touchscreen display.

Additionally, Longer has also added a plastic strain relief bracket that you can mount underneath the heated bed and will help support the PSU cable. Almost everything is made of metal, with the exception of a few elements, such as the filament holder which has proven to be strong enough to keep a heavy roll of filament. The hotbed is made of metal and it can reach up to 100 degrees C (212 degrees F), but, because it is not insulated, it will take a bit longer until it heats up. I also need to mention the additional glass bed that you can put on top of the hotbed and it’s a great addition since it’s far easier to detach the models this way (none had to be forcibly removed, they just pop off). The surface is also far more even when dealing with glass, as proven by the calibration (manually, with a sheet of paper). I know that some of you may have liked to see a print chamber, but that’s still impossible at this price point.

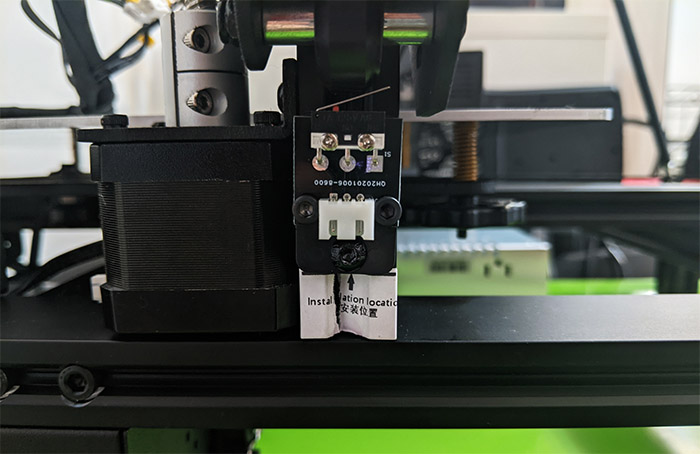

You do get the triangle shape design and I did like that the teflon tube that goes from the extruder to the hotend can sustain temperatures up to 280 degrees Celsius (536 F), but be aware that the supported temperature only goes up to 250 degrees C (482 F). Another cool element is the filament run-out sensor which automatically pauses the print in case it detects that you ran out of filament and then it resumes the printing after you’ve added it back. This is also true in case there’s a power outage, so you don’t have to worry about re-starting the print because the Longer LK5 Pro will continue where it left off after the power is restored. Initially I wasn’t very sure about the hotend fan duct since it’s pretty much the same one as on the LK4 Pro, but it does seem to fare decently well. You always have the option to print its upgrade, so it can be improved if you have issues with it.

Putting Everything Together

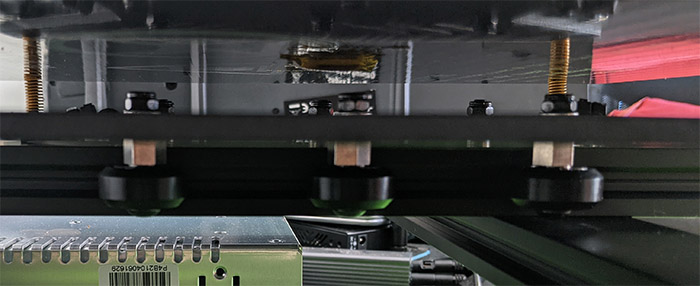

The first thing that you can take out of the box is the gantry, as well as the screw rod and the two supporting rods. Then there’s the spatula, the card reader and the microSD card – when you remove this section, be careful that the glass bed is not connected to the assembly, so it may fall and shatter (we don’t want that). The rest of the 3D printer is pretty much already pre-assembled, but there are some important parts to be added. Before attaching anything, I turned the pre-assembled part of the printer upside down and, as you can see, Longer used plastic feet which can (and should) be replaced with silicone ones. The plastic feet do absolutely nothing against jerks or shakes, while the rubber feet are great at absorbing some of the vibrations.

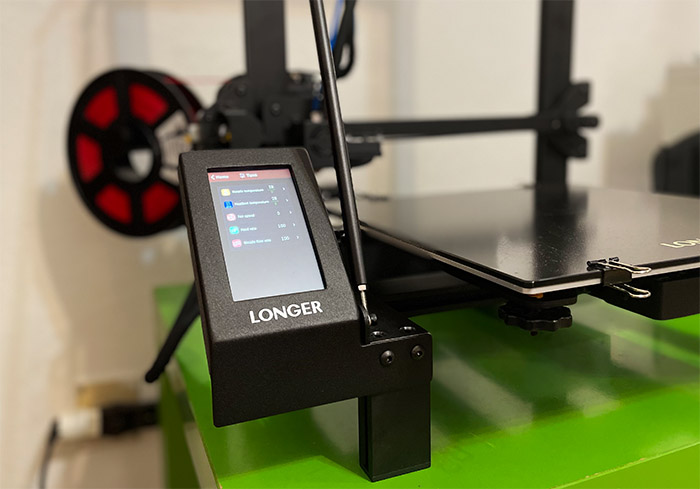

Then there’s the P360W24V power supply from Chengliang and it’s a fairly generic one, but should do the job properly. The fans have always been a weakness of the Longer 3D printers since they were very loud and the LK5 Pro does have three fans (besides the PSU fan) – one on the frame base and two at the end of the X-axis beam (for the hotend).

The interesting thing is that the fans are not as loud as on the LK4 (which pushed 12V fans to 24V), quite far from it, but they’re still the most audible part since Longer has made everything else almost silent – with the exception of the extruder. To see why, I decided to open up the main section and I had to remove quite a few screws with one of the provided Allen keys. This way, I was able to see that there’s a LGT_KIT_V1.0 board which has three removable silent steppers (TWC2208) with small heatsinks at the top and the processor is a an 8-bit Arduino ATMEGA2560. The extruder does get a different stepper driver (as I anticipated) and it’s not the silent type (couldn’t identify it), but the good news is that you can replace it if it bothers you.

If you look around the PSU, you will see that there’s a sticker which has instructions to switch between 230V and 115V, depending on the country you’re in – since I was in Europe at the moment of writing, I left the switch to 230V, which was the default, but I know that in the USA, you need to change it to 115V.

After that’s done, it’s time to start the assembly and, following the instructions from the box, we need to roll the X-axis beam through the gantry poles, then take the assembly screw rod and rotate it into the X-axis beam dedicated brass nut. Next, I took the X-axis motor and two M4*16 screws and tightened the motor to the gantry. Afterwards, I inserted the screw rod into the top part of the motor and, after loosing up the screws of the coupler, the rod slipped right in. You will now be able to adjust the height of the X-axis beam. The next step requires four M5x20 screws and you need to use them to attach the gantry to the base. It’s very difficult to do it from the bottom, so it’s best to take the whole assembly and put it on its side, to easily insert the screws into place. Now it’s time to add the support rods and to do so, you need to use four M4*8 bolts and make sure that there’s a 90 degrees angle between the gantry and the base. I needed to adjust the support rods a bit since the angle was indeed off and the use of the rods is an absolute necessity if you connect two tall pillars using four bolts.

After that’s done, connect the limited switch and the filament holder using two M4*16 and two M5*20 bolts. The limited switch goes at the top to keep the screw rod into place and the filament holder goes to the top of the beam of the printer. I was a bit taken aback by the filament holder on the Selpic Star A Mini 3D printer, but here, it seems to be a bit more sturdy, despite also being made of plastic. AFter that, we need to install the display and the area where it needs to be added is pretty obvious since it’s the only section that has exposed aluminum. So, take two M5*6 bolts and attach the display, and also connect the Z-axis limit switch near the X-axis motor. Next, we need to connect all the wires, so go ahead and attach the Z cable to the Z-axis limit switch, another Z-cable with more pins goes to the motor and the LCD cable goes to the back of the display. The thick PSU cable goes to the rear of the metallic bed and then add the E-cable with more pins to the extruder module, while the other E-cable goes to the filament detector. The other two X-cables go to the motor.

We are not done yet because you will need to use the provided wrench to stabilize the bed. There are three screws underneath that you need to tighten (or loosen), so that the bed will lose the wobbling effect – you can use the moving plastic wheels to have a feel at how tight the screws are. And now it’s time to adjust the hotbed – to do so, start the printer (switch the power to on) and from the display, tap on the Leveling tab. You will now see five points and you need to tap on each at a time and then adjust the wheels from underneath the bed until all five parts allow you to move a sheet of paper with only a little bit of resistance.

It’s important to know that you will have to go to 4 and then back to 1 several times until the hotbed is properly leveled and yes, it may take quite a few minutes (I played around for about 20 minutes). I noticed that the springs are good quality, but the knobs could have been bigger since it’s not that easy to move for adjustment – you can now print new knobs. Before starting printing anything, it’s good to also check that the X-axis motor moves smoothly and if it’s not, take the wrench and adjust the screw from underneath the motor.

The Display

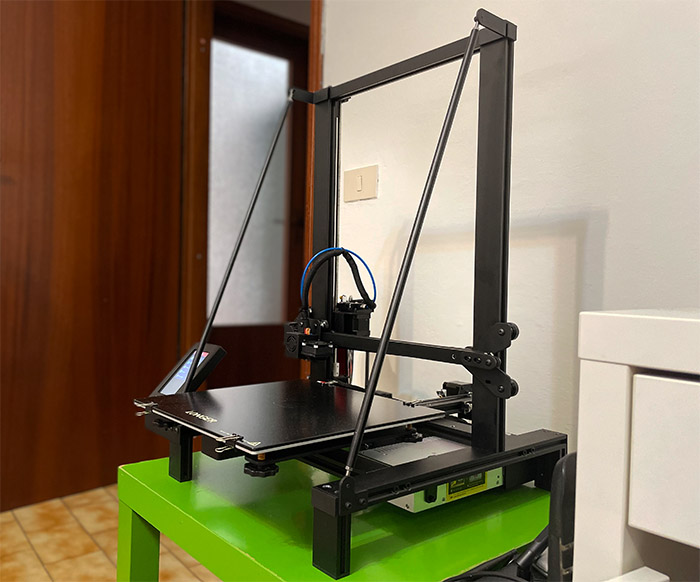

The Longer LK5 Pro does have the same color display as the LK4 Pro and it’s still pretty good. It is touchscreen, so there are no buttons and it is usually very responsive with the exception of some areas where the tabs are too narrow – so I had to try two, three times to get the area right. Other than that, the LCD is fast and responsive. After powering on the 3D printer, the display will immediately show six tabs, the first is called Move and it is essentially allowing you to manually move the hotend around (you can also return it to home), while the second tab is the File. Here you can see all the available 3D models that can be printed. That’s only if you either have inserted a microSD card or have connected an external drive or computer to the USB port.

The third tab allows you to Tune the LK5 Pro (bed and nozzle temperature, the fan speed, the flow rate and the nozzle flow rate), while the fourth tab allows you to add or remove the filament, as well as select the type (it will work with ABS and PLA). The last two tabs can be used for Leveling the hotbed and to check some info about the Longer LK5 Pro.

What’s great is that you can adjust your prints from the LCD display and not having to re-slice the model again as you would with other inexpensive 3D printers.

Longer LK5 Pro

-Pros

- The printer is fairly silent and less prone to vibrations due to the improved design

- Can be easily upgraded

- It has a hotbed + separate glass bed

- Not too difficult to adjust and configure + color touchscreen display

- The 3D models are well printed

Cons

- I'm nitpicking at this point, but the new-comers may be intimidated by the assembly process and by all the necessary adjustments that need to be made afterwards

Mark is a graduate in Computer Science, having gathered valuable experience over the years working in IT as a programmer. Mark is also the main tech writer for MBReviews.com, covering not only his passion, the networking devices, but also other cool electronic gadgets that you may find useful for your every day life.